Solaris Biotech and Scaling Cultivated Meat: Driving Bioprocessing Innovations

This article was written and sponsored by Solaris Biotech.

As cultivated meat companies look to commercialize, there are still many scaling challenges that companies need to address, particularly around bioprocessing.

In an interview with Katrien Verbrugge, the Director of Global Sales for Bioprocessing Equipment of Solaris Biotech, companies like Solaris Biotech are best positioned to support the field through scaling production through their bioprocessing solutions. Having worked with different cultivated meat and seafood companies, Verbrugge highlights how Solaris Biotech can help the industry achieve its goals of becoming part of a sustainable food system.

Can you please introduce Solaris Biotech by Donaldson? Now that you are part of Donaldson Life Sciences, can you highlight their role in advancing biomanufacturing and bioprocessing solutions?

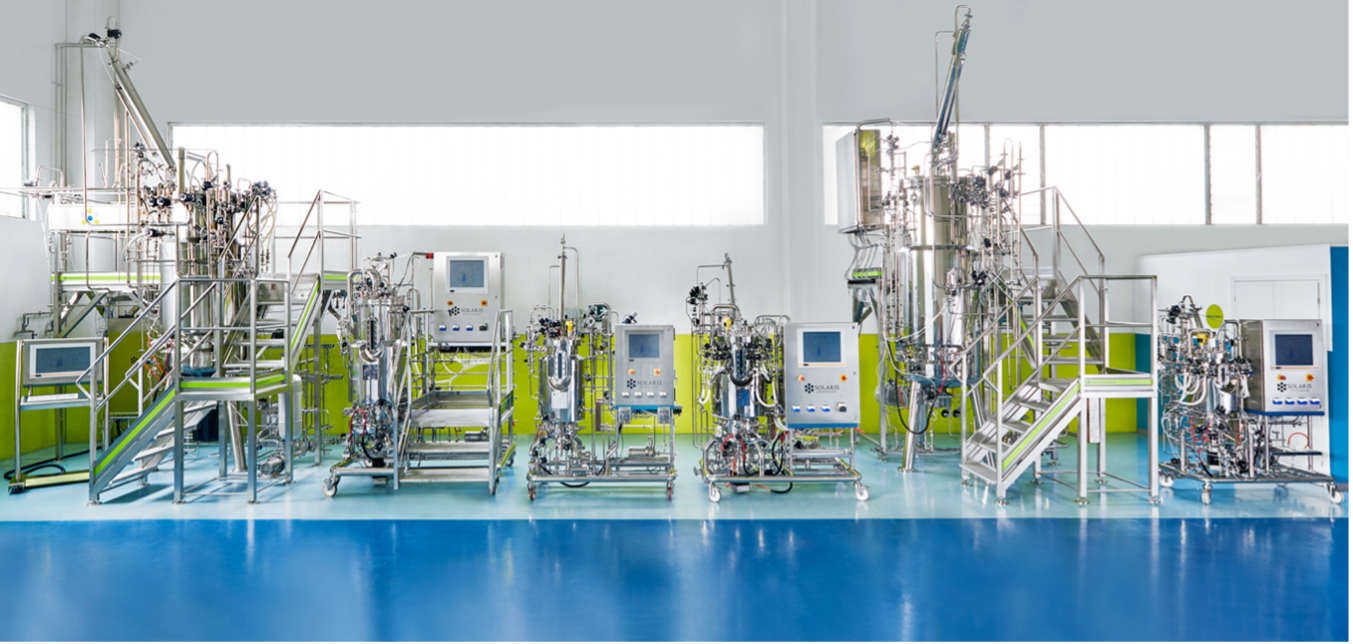

Solaris Biotech is a provider of innovative biomanufacturing solutions, offering a comprehensive range of equipment, including benchtop, pilot, and industrial-scale bioreactors, fermenters, and filtration systems. These cutting-edge technologies serve diverse industries, including pharmaceuticals, food production, agriculture, and biochemicals, supporting both research and large-scale production. With a global network of production, sales, and service teams, Solaris Biotech delivers innovative solutions to meet the evolving needs of our international customers. Incorporated in 2002, we are now a part of Donaldson Company (NYSE: DCI).

Our mission is to provide advanced yet accessible solutions, with unique benefits in terms of quality and flexibility and to be our client’s partner of choice.

Long a pioneer in filtration solutions, Donaldson Company (NYSE: DCI) continues to expand into the Life Sciences sector. The Bioprocessing division is concentrated on developing solutions from R&D to commercialization for multi-modality drug manufacturers. With Donaldson Life Sciences we are driven to continuously innovate, evolve, and deliver Smarter Bioprocessing solutions that help developers improve global health.

Considering Solaris’ experience working in the life science industry, how is Solaris uniquely positioned to support the cultivated meat industry?

At Solaris, we innovate for sustainability in life sciences and food industries. Leveraging our expertise in fermentation, we proudly support the cultivated meat industry, advancing a sustainable future for food production.

Over the years, we have partnered with startups, universities, and research centers to advance the alternative protein sector, continuously refining our tools and processes to meet the evolving needs of this fast-growing industry. This collaborative approach underpins our mission: to provide the technical foundation for a more sustainable and ethical food system, making the vision of cultivated meat a scalable reality.

Our specialization in bioprocess development enables us to address the unique challenges of cultivated meat production. This includes developing bioreactors and processes optimized for cultivating animal stem cells—an intricate task given their sensitivity to shear forces, lower growth rates compared to microbial systems, and reliance on specialized growth media. By leveraging our deep understanding of scaling bioprocesses from research to industrial production, we help our partners achieve consistent and efficient production outcomes across all scales, from lab environments to vessels capable of holding thousands of liters.

The key challenge facing the cultivated meat industry will be scaling production of cell-cultured meat from lab-scale to commercial scale production. How does Solaris look to support the industry in achieving its goals?

Solaris has been at the forefront of supporting the alternative protein sector and cultivated meat industry, leveraging over two decades of experience collaborating with startups, universities, and research centers. Our mission is to enable the scale-up of cell-cultured meat production by providing the advanced bioprocessing tools and expertise necessary for this transition.

One of our core innovations lies in ensuring a seamless scale-up process within bioreactors, from R&D to industrial-scale production. We design and supply bioreactors capable of handling the unique challenges of cultivating animal cells, such as their sensitivity to shear forces and the precise environmental control they require. By maintaining consistent growth conditions across scales—ranging from lab-scale systems to vessels capable of holding thousands of liters—we help preserve the integrity and quality of cell-cultured products as production volumes increase.

This scalability is critical for bringing cultivated meat to market at competitive costs while maintaining high standards of safety and sustainability. By partnering with industry pioneers, we’ve helped bridge the gap between scientific innovation and commercial production, driving forward the potential of cultivated meat to transform the global food system.

At Solaris Biotech, we collaborate with companies at every stage of their bioprocess journey, offering tailored solutions from lab-scale research to full industrial production. Our approach is highly adaptable, ensuring that we meet the unique needs of each client:

Comprehensive Support Across All Scales:

- We provide scalable bioreactor and bioprocessing solutions, from benchtop units for R&D to industrial systems capable of handling thousands of liters. Our technology also allows for parallel processing with up to 24 units, optimizing efficiency and throughput.

Turnkey Project Expertise:

- Solaris offers end-to-end project support, including feasibility studies, engineering, and the delivery of turnkey solutions. Our expertise spans upstream and downstream processes, as well as tangential flow filtration (TFF) systems, ensuring a complete and integrated approach to bioprocessing.

Flexibility in Engagement:

- Companies can engage with us at any stage, whether they’re in the early R&D phase or scaling up for commercial production. However, the earlier we are involved, the more we can optimize the process design and scale-up strategy, ensuring seamless transitions and cost-efficiency throughout the project lifecycle.

Revamping and Customization:

- For companies with existing infrastructure, we also specialize in revamping and upgrading equipment to enhance performance and align with evolving production needs.

By partnering with Solaris, companies gain access to a team that combines technical expertise, innovative technology, and a commitment to delivering tailored solutions, enabling success at every stage of their bioprocess development and production.

Are there any upcoming events, trade shows, or conferences where industry professionals can meet and engage with Solaris Biotech? What can attendees expect to learn or gain from interacting with your team at these events?

Solaris Biotech has an exciting lineup of events and trade shows where professionals in the cell agriculture and biotech industries can connect with our team. From Asia to Europe, and across the United States, we’ll be participating in key global gatherings that focus on innovation in fermentation, bioprocessing, and alternative protein production.

Kicking off with The Future of Protein Production 2024 in Amsterdam this October, we’ll also attend the MEVO 2025 Annual Meat Evolution Leaders Summit in Singapore and the World Agri-Tech Innovation Summit in San Francisco on March 19–20. These events will highlight advancements in cultivated meat, agri-tech, and sustainable protein production.

Other notable stops on our calendar include the Biologics Conference and Workshop in Goa, Analytica China in Shanghai, the Congrès France Bioproduction, Probiota Global 2025 in Copenhagen, the Pittcon Conference in Boston, and SynBioBeta 2025. Each event provides an opportunity to engage on topics such as alternative proteins, synthetic biology, cell therapy, and advanced bioreactor technologies.

At these venues, attendees can explore Solaris’ latest innovations through interactive demonstrations and in-depth discussions with our experts. Whether you’re looking to optimize processes, overcome scale-up challenges, or explore emerging trends, Solaris will provide actionable insights and practical solutions tailored to your needs.

This article was written and sponsored by Solaris Biotech.

Stay connected with CellAgri

Join our mailing list to receive the latest news and updates weekly from the cellular agriculture industry. Your information will not be shared.